Once upon a time, telemark skis were skinny and the boots were leather. In the mid-1980’s, home-grown telemark equipment that incorporated the features of alpine gear started to appear.

At that time, the state of the art off-the-shelf telemark boots included the Asolo Extreme, which was a lace-up ankle-high leather boot with a plastic stiffener around the ankle area. Next came the Asolo Extreme Pro, which added a little height, more internal plastic, and a buckle. The Extreme Pro was a great telemark boot, and I used a pair until the late 1990’s. I reluctantly made the switch to plastic because the wet snow in the Northwest eventually reduces leather to a pulpy, shredded mess.

Although Asolo pretty much owned the “old school” telemark boot market, the eye-catching Merrell Supercomp, which had a leather lower and a flashy white plastic cuff, also adorned the feet of some speedy telemark skiers.

Either way, early telemark activists pushed the limits of this kind of gear, and since manufacturers weren’t meeting our needs, we took it upon ourselves to migrate the technology away from its “pinhead” roots.

The most common modification was to add plastic to an Asolo Extreme. The typical way to do this was to make cuffs out of a plastic bucket (hence the name “pickle bucket boots”), rivet them to the leather lower, and add a ski boot buckle or two. An enhanced version was to rivet or otherwise attach an actual alpine boot upper to an Asolo leather lower.

I managed the Christy Sports at the base of Beaver Creek in Avon, CO. At the tender age of 25 I had 7+ years of experience as a ski mechanic. Therefore, I was occasionally consulted on some of the trickier customizations. Needless to say, libation was typically provided in exchange for my services, which in turn enhanced the creative abilities of the equipment tinkerers.

Also, to put things in perspective, at that point in time, the ski industry equipment standards that currently define the ski-boot-binding interface were just becoming fully implemented. Ski mechanics in those days sometimes had to problem-solve to make boots and bindings work together. We applied that same creativity to modify our free heel equipment setups.

One memorable customization involved a pair of Salomon SX91 Equipe boots, Spademan bindings, and Hexcel Comp skis.

The red and white SX 91 Equipes were Salomon’s second generation rear-entry boot, and a hot seller. We used a bandsaw to cut them in two at the ball of the foot. My friend’s dad owned a local machine shop and he was able to sneak in and build custom hinges to go under the ball of the foot. We riveted and shoe-gooed a plastic bellows in over the top of the ball of the foot. We manufactured what may have been the first all-plastic free-heel boot.

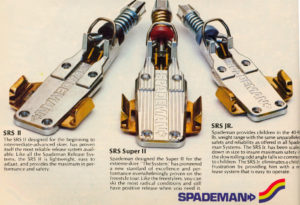

Spademan bindings were an artifact from the days of the 1970’s hotdoggers, and consisted of a simple, ingenious design. Instead of attaching at the toe and heel, Spademans attached via a metal plate screwed to the bottom of the boot under the tibia. The idea was that this gave the system a more accurate way of sensing the forces actually experienced by the leg, and minimized the force-related variables involved with toe-heel bindings that existed at that time.

In this case, we mounted the Spademan boot plate under the forefoot of the modified Salomons, and reverse-mounted the bindings on the skis. In a normal installation the spring on the Spademans pointed to the back of the skis. In this case the spring pointed forward. To get into the binding you simply stepped in with the forefoot and clamped the spring closed. I don’t remember exactly where we mounted the binding on the ski, though I’m sure we stood around speculating and sipping the libation for a while before we started to drill.

Hexcel skis were another artifact from the 1970’s, and featured a lightweight aluminum honeycomb core. The honeycomb core meant there was nothing solid to screw the bindings into, and the mounting process involved routing out a space in the core and then using a special epoxy to hold the binding screws in place. Much more complicated than the pre-drilled systems that are common now.

Although we had created a system everyone was eager to try, I didn’t really like the way it skied compared to a conventional telemark setup. The heavy alpine boot felt relatively dead and insensitive compared to a leather boot with a vibram sole. On the other hand ripping stable tele turns at 40mph was a blast.

The recent changes in telemark boots and skis have really made telemark skiing a whole lot easier. By retaining the vibram sole, the new age boots maintain the sensitivity of the original leather gear, and the evolution of shaped skis has absolutely transformed the telemark turn.

Whatever you ride, have fun.

Album: 1986 Vikin Fjord Nor-Am Telemark National Championships